Antonia Hahn

How computers learn to see – Applying AI to industry

#1about 1 minute

The challenge of quality control in car seat manufacturing

A car seat manufacturer needs to ensure hundreds of special clips are correctly placed on various seat types daily.

#2about 1 minute

Evaluating solutions for automated visual inspection

AI-based inspection is a superior solution compared to manual checks, which are error-prone, or classic computer vision, which requires extensive programming.

#3about 2 minutes

Understanding AI use cases for computer vision

AI uses statistical algorithms for tasks like image classification, object detection, and even generating new images with generative AI.

#4about 4 minutes

Preparing and pre-processing data for a machine learning model

The preparation phase involves clarifying the task, choosing a technical setup, collecting and labeling data, and splitting it into training, validation, and test sets to prevent overfitting.

#5about 2 minutes

A simplified overview of convolutional neural networks

A Convolutional Neural Network (CNN) uses layers like convolutional, pooling, and dense layers to learn features from images and make predictions.

#6about 2 minutes

Building from scratch vs using pre-trained models

Using a service provider with pre-trained models is more time and cost-effective, requiring far fewer images than building a model from scratch.

#7about 3 minutes

Evaluating model performance with a confusion matrix

A confusion matrix helps evaluate model performance by comparing actual to predicted values, highlighting critical metrics like false negatives and the escape rate.

#8about 2 minutes

Iterating and fine-tuning the model for better results

Improving model performance is an iterative process of collecting more data, adjusting pre-processing steps, trying different models, and tuning parameters using the validation dataset.

#9about 2 minutes

Deploying the AI model into a production environment

The final deployed system uses a camera, a classifier to identify the seat type, the inspection model, and a post-processing module to trigger actions like a robot arm.

#10about 1 minute

Key takeaways for applying AI in manufacturing

AI is a feasible solution for visual inspection in manufacturing, especially when using pre-trained models and embracing an iterative, experimental approach.

#11about 1 minute

Q&A on data sourcing and finding pre-trained models

The Q&A covers the necessity of collecting images directly from the customer's assembly line and finding pre-trained models from cloud providers or open-source repositories.

Related jobs

Jobs that call for the skills explored in this talk.

(Senior) Data & AI Consultant / Banking (all genders)

msg

Ismaning, Germany

Intermediate

Senior

Data analysis

Cloud (AWS/Google/Azure)

Full Stack Developer (all genders welcome)

ROSEN Technology and Research Center GmbH

Osnabrück, Germany

Senior

TypeScript

React

+3

Cloud Engineer (m/w/d)

VECTOR Informatik

Stuttgart, Germany

Intermediate

Senior

DevOps

Cloud (AWS/Google/Azure)

Matching moments

22:45 MIN

Applying machine learning in the automotive industry

Getting Started with Machine Learning

11:36 MIN

Use case: AI-driven foreign object detection in manufacturing

From Factory Floor to Kubernetes Core: Building an Edge Platform One Step at a Time

38:31 MIN

Previewing the "AI or knockout" conference talk

From Learning to Leading: Why HR Needs a ChatGPT License

25:29 MIN

Lightning round on future skills and AI trends

The AI-Ready Stack: Rethinking the Engineering Org of the Future

29:52 MIN

Skills and challenges of working with automotive AI

Developing an AI.SDK

00:05 MIN

AI's growing role in the software development lifecycle

The AI-Ready Stack: Rethinking the Engineering Org of the Future

01:32 MIN

Practical examples of using AI in daily life

Collaborative Intelligence: The Human & AI Partnership

11:57 MIN

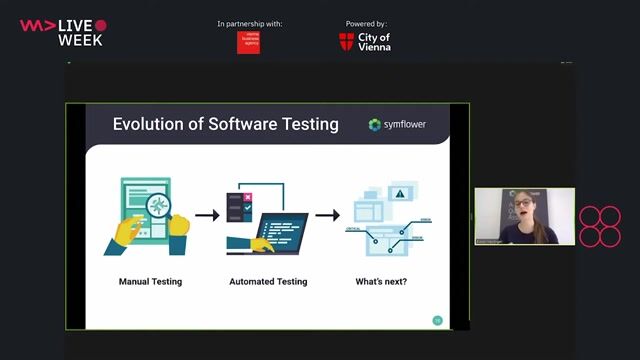

Envisioning the future of testing with artificial intelligence

How will artificial intelligence change the future of software testing?

Featured Partners

Related Videos

35:16

35:16How AI Models Get Smarter

Ankit Patel

1:09:49

1:09:49Inside the AI Revolution: How Microsoft is Empowering the World to Achieve More

Simi Olabisi

25:14

25:14The shadows of reasoning – new design paradigms for a gen AI world

Jonas Andrulis

29:00

29:00AI in Action: Real Use Cases with Real Impact - Hanna Hennig, Michael Ameling, Tobias Regenfuss

Hanna Hennig, Michael Ameling & Tobias Regenfuss and Mike Butcher

28:19

28:19Robots 2.0: When artificial intelligence meets steel

Thomas Tomow

31:15

31:15The AI Skills Gap: What Tech Leaders Must Get Right

Thomas Wollmann, Gerrit Einhoff, Kara Sprague & Alexandra Wudel

28:19

28:19AI in Leadership: How Technology is Reshaping Executive Roles

Jeff Hausmann, Jasmin Kaiser, Bernd Datler & Sonja Alvarez

41:06

41:06Panel: How AI is changing the world of work

Pascal Reddig, TJ Griffiths, Fabian Schmidt, Oliver Winzenried & Matthias Niehoff & Mirko Ross

Related Articles

View all articles

From learning to earning

Jobs that call for the skills explored in this talk.

Senior Machine Learning Engineer (f/m/d)

MARKT-PILOT GmbH

Stuttgart, Germany

Remote

€75-90K

Senior

Python

Docker

Machine Learning

Machine Learning & Data Engineer - AI for Autonomous Systems

RIB Deutschland GmbH

Stuttgart, Germany

Python

Machine Learning

ML Data Engineer - Object Detection & Active Learning

autonomous-teaming

München, Germany

Remote

ETL

NoSQL

NumPy

Python

+3

ML Data Engineer - Computer Vision, Video & Sensor Data

autonomous-teaming

Canton of Toulouse-5, France

Remote

ETL

NoSQL

NumPy

Python

+4

AI & Embedded ML Engineer (Real-Time Edge Optimization)

autonomous-teaming

München, Germany

Remote

C++

GIT

Linux

Python

+1

AI Content Expert, Artificial General Intelligence

Amazon.com, Inc

Shoreham-by-Sea, United Kingdom

XML

HTML

JSON

Python

Data analysis

+1

Working Student - AI Solutions & Process Automation

Continental AG

Hannover, Germany

Remote

GIT

Python

Microsoft Office