Senior Design for Manufacture Engineer

Role details

Job location

Tech stack

Job description

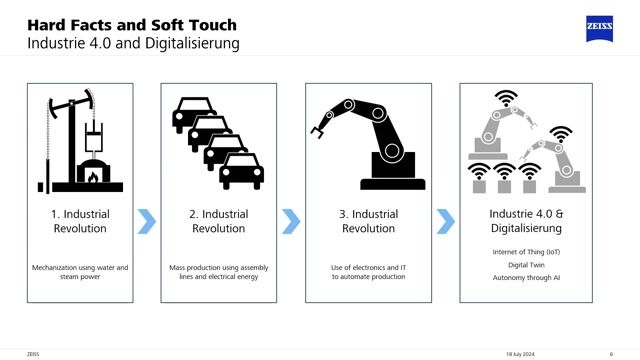

This role will join a long-term, multi-year programme delivering safety-critical nuclear Instrumentation & Control (I&C) systems for reactor protection. This role is pivotal in ensuring that complex, high-integrity electronic and electromechanical systems are designed with scalable, supportable, and cost-effective manufacturing in mind - from concept through to 60 years of in-service support., * Develop and implement innovative Design for Manufacture (DfM) processes to support the creation of scalable, efficient, and cost-effective production systems

- Collaborate with design, systems, and manufacturing teams to embed DfM principles early in the product lifecycle.

- Develop and optimise manufacturing processes for high complexity, medium volume production of safety-critical equipment.

- Support the definition and implementation of business and engineering processes to enable scalable, repeatable manufacturing.

- Drive automation opportunities and digital manufacturing strategies to improve quality, consistency, cost and throughput.

- Contribute to the selection and qualification of suppliers and manufacturing partners.

- Ensure that design decisions consider long-term supportability, obsolescence management, and maintainability over a 60-year lifecycle.

- Take a lead role in design reviews, DFMEAs and PFMEAs, and process validation activities.

- Provide technical input into make/buy decisions and cost modelling.

Requirements

Do you have experience in Systems engineering?, * Security contractual compliance will require incumbents must be a sole British National

- Proven experience in Design for Manufacture within a high-integrity or regulated environment (e.g. aerospace, defence, nuclear, automotive).

- Knowledge of quality standards, specifically ISO 9001.

- Strong understanding of automated manufacturing techniques and their application to complex assemblies.

- Experience working in cross-functional engineering teams.

- Familiarity with lifecycle management and configuration control.

- Excellent problem-solving and communication skills.

Desired Skills:

- Degree in Mechanical, Manufacturing, or Systems Engineering (or equivalent experience).

- Knowledge of relevant standards (e.g. IEC 61513, AS9100, NQA-1).

- Exposure to digital manufacturing tools and PLM systems.

- Experience of introducing robotics and collaborative robotics (cobotics) into manufacturing workflows